Understanding Monoflange Valve- Types and Applications Details

Understanding Monoflange Valve- Types and Applications

No country or society today can succeed without adopting engineering at some level. Engineering has application to almost all sectors. It plays a major role in modern society by providing advanced technology to shape at the national and global level. Today, we are going to know about Monoflange valves which are widely used in oil & gas, petrochemical, refining and chemical industries.

LET US SEE WHAT MONOFLANGE VALVES ARE

Monoflange valves are used as an alternative to multiple valve systems. The monoflange consists of a vent hole, a block valve and a bleed valve. They are designed specifically to provide installation for instruments such as transmitter and gauge. Monoflange valve enables the shutting off and venting of pressure measuring instruments. They function like traditional valves, but are particularly compact and also suitable for processes involving aggressive substances. There are two series of monoflange valves; they are process monoflange and instrument monoflange.

KEY ADVANTAGE OF USING MONOFLANGE VALVE

Reduction in potential leak

Monoflange valve reduces the number of paths which prevents potential leak thus creating a compact system.

Reduction in weight

The significant weight as well as the cost of components is lowered when compared to other kinds of installation. Monoflange can be configured either as a single block and bleed or double block & bleed with the presence of clogged vent port for the bleed.

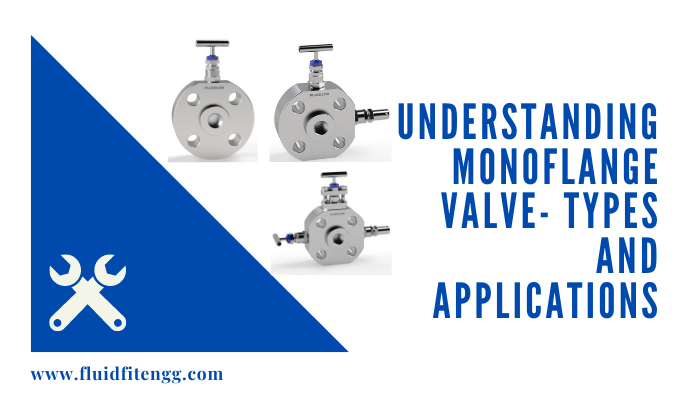

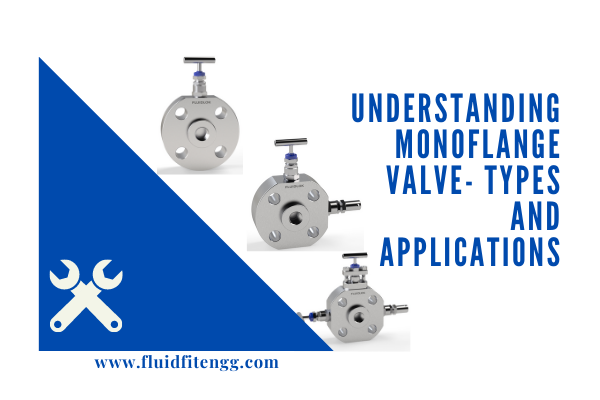

TYPES OF MONOFLANGE VALVE

There are various types of valves which are suitable for the usage of monoflange valves, they are single isolation valve, monoflange block & bleed valve, monoflange DBB (Double Block & Bleed) valve.

1. Isolation Valve

It is the simplest monoflange valve. This variant has only one shut-off valve.

2. Monoflange Block & Bleed Valve

The block and bleed variant has an additional vent valve for safe venting, eg:- during commissioning.

3. Monoflange Double Block & Bleed Valve

The double block and bleed variant has a second shut off valve for the redundant shut-off of the process.

APPLICATIONS OF MONOFLANGE VALVES

Monoflange valves have various applications in industries such as oil and gas, refineries, chemical industries and many more. Some of its application includes:

- They are used for measuring gases, liquids as well as vapors.

- They are also used for corrosive pressure media in aggressive environments.

- They are also used in industrial process plants within general plant construction, machine building, chemical or petrochemical, mining industries and power stations.

Final Words:

So far, we have seen what monoflange valves are, their types and its benefits. As they are considered to be durable, precise and long lasting, it makes them cost-effective solutions for various industrial purposes. If you are looking for a monoflange valve, please visit our website and get the best products with best deals.

Categories

- Monoflange Valves (1)

- Block & Bleed Valves (1)

- Tube Fittings (0)

- Needle Valve (0)

- Ball Valve (0)

- Events (1)

Recent Post