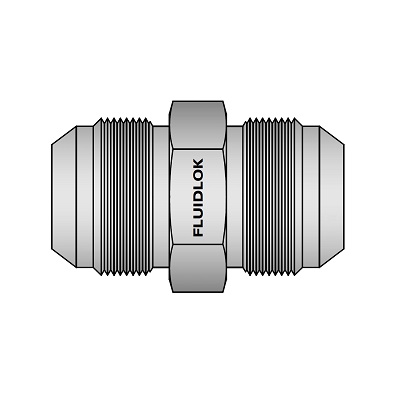

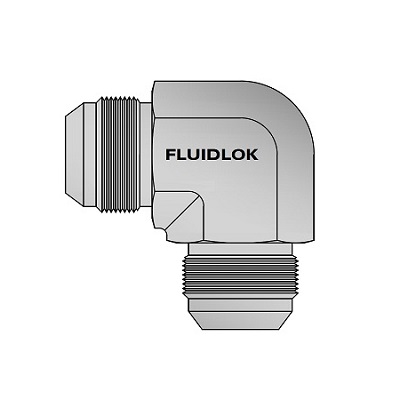

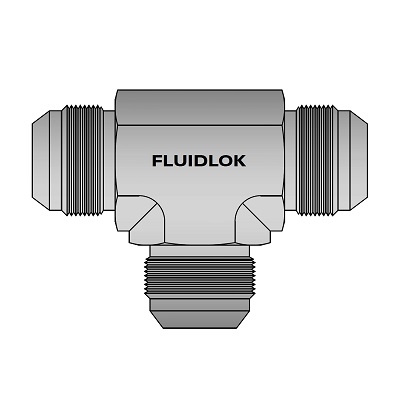

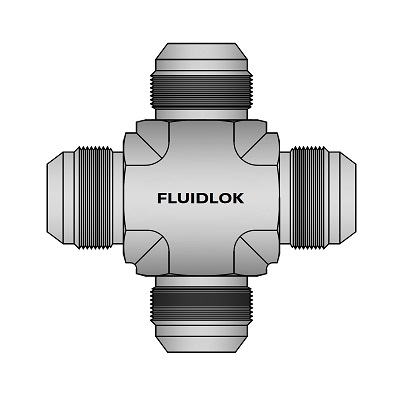

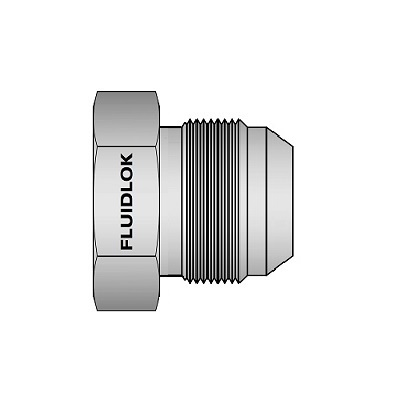

JIC 37° Flare Fittings

We at FLUIDLOK not only strive to meet all our customer’s requirements but also enhance customer’s expectation by providing them excellent products at economical price in time. 37° Flared Tube Fittings are designed such that upon tightening the nut, the sleeve ensures that the tube axis is perfectly aligned with the fitting body axis thus reducing the mechanical strain on the tubing.

Our flared fittings- three precision component tube assembly are manufactured in accordance with SAE J514 Standard. These JIC fittings are available in carbon steel & stainless steel and are compact and simple in design for assembly and assures maximum reliability and performance. It is especially suited for low and medium wall tubing with good vibration resistance in a broad selection of types and sizes. It is used in virtually every application that uses fluid power for motion control & automation. These products are used in the environments like oil, gas, chemical, petrochemical, nuclear power plant, pharmaceutical, hydraulic, pneumatic, marine, packaging, printing industries etc.

FLUIDLOK flared Tube Fittings consist of three precision components such as Body, Sleeve and Nut. These components have been manufactured to very stringent tolerances under rigid quality control procedure approved to ISO 9001:2008 and meets SAE J514 standard. The tube end is flared at a 37° angle and sandwiched between the fitting body nose (seat) and the sleeve with nut which provide a very effective leak-proof joint, full flow connection in process tubing. These come in sizes ranging from 1/8” to 1” and 6mm to 25mm for fractional and metric sizes respectively with pressure rating up to 5000 psi.

Our fittings are designed and manufactured with a goal to provide excellent services and meet all the requirements by our customers. For more details, please refer our catalog.