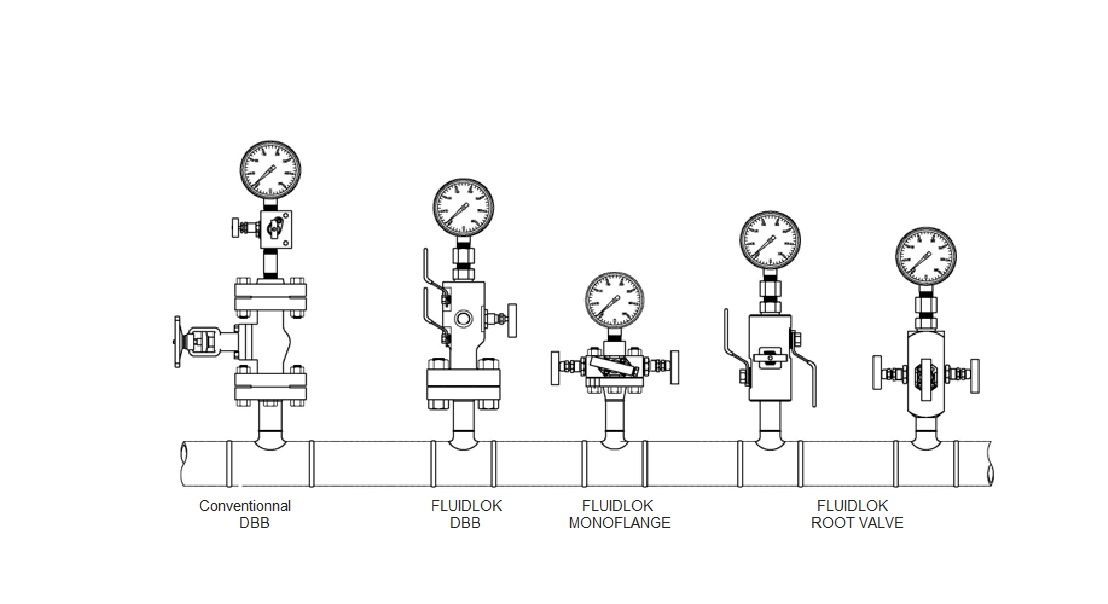

Double Block & Bleed Valve

Double Block and Bleed valves are used as an alternative to a system which has multiple valves. FLUIDLOK DBB Valves are designed in an integrally forged body or barstock body specifically to provide a compact design with strength thereby reducing potential leak paths, system mass which in turn reduces the total weight, vibration, making it rigid, safer and cost efficient. These valves find their application in various industries like oil and gas, chemical, refinery, power plant, etc.

Our DBB valves are further classified as Monoflange Valve and Integral Body Double Block and Bleed Valve, available in various configurations and sizes and manufactured in stainless steel, carbon steel, monel, duplex, super duplex, etc. in accordance with standards such as ASME B16.5, ASME B16.34, ASME B16.10, API 6D (fire-safe is optional)

Our valves are 100% factory tested hydrostatically with respect to maximum allowable working pressure to a requirement of no visible leakage. Shell test is performed at 1.5 times the maximum rated working pressure and 1.1 times for a seat test in accordance with BS EN 12266-1 and API 598.

FLUIDLOK provides capabilities and competence in bespoke customizing with these valves to serve specific requirements of your needs. Please refer our catalogue for detailed information.