What is DBB Valve (Double Block and Bleed Valve)? Details

What is DBB Valve (Double Block and Bleed Valve)?

A double block and bleed (DBB) valve is a type of valve that provides isolation between two separate process lines and also allows for venting of the area between the two valves. This design offers a significant safety advantage over traditional block and bleed valves by providing redundant isolation and venting capabilities.

The DBB valve has two separate valves that are integrated into a single body. Each valve can be operated independently, allowing for individual isolation of the process lines. This means that if one valve fails, the other valve can still isolate the line, reducing the risk of process fluid leakage.

The venting capability of the DBB valve is also an important safety feature. The area between the two valves can be vented to atmosphere or to a drain, which allows for safe and controlled release of any trapped fluids or gases. This prevents the buildup of pressure or the accumulation of hazardous materials in the space between the valves, which can be dangerous for personnel or equipment.

DBB valves are commonly used in applications where the safety of personnel and equipment is critical, such as in the oil and gas industry, chemical processing, and power generation. They are often installed in high-pressure or high-temperature applications, where the consequences of a failure could be severe.

There are different types of DBB valves, including ball valves and needle valves. Each type of valve has its own unique features and benefits, and the selection of the appropriate valve depends on the specific application requirements.

Ball valves are commonly used in DBB applications because they offer low torque operation and require minimal maintenance. They are also easy to operate and can provide tight shut-off capabilities.

Needle valves are also commonly used in DBB applications because they can provide a positive seal and are suitable for high-pressure applications. They are often used in pipeline isolation and other critical applications.

In addition to the type of valve used, the material of construction is also important in DBB applications. The materials must be able to withstand the process fluid and any environmental factors, such as temperature and pressure.

In summary, a double block and bleed valve is a critical component in ensuring the safety of personnel and equipment in high-pressure and high-temperature applications. By providing redundant isolation and venting capabilities, DBB valves offer a significant safety advantage over traditional block and bleed valves. The selection of the appropriate type of valve and material of construction is important to ensure reliable and safe operation.

Categories

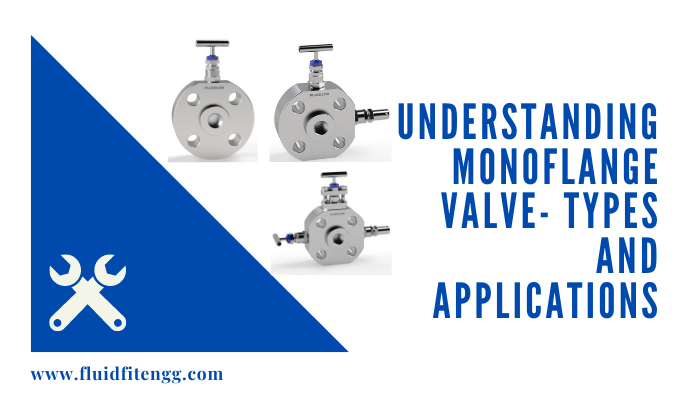

- Monoflange Valves (1)

- Block & Bleed Valves (1)

- Tube Fittings (0)

- Needle Valve (0)

- Ball Valve (0)

- Events (1)

Recent Post