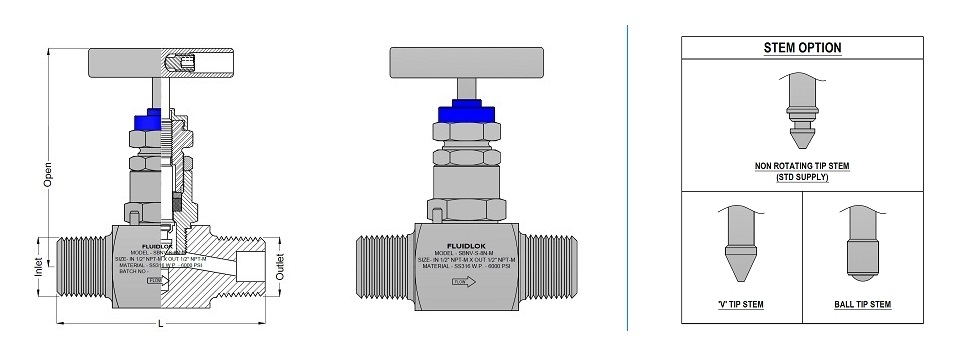

Screwed Bonnet Needle Valve - NPT Male X NPT Male

Application:

Features:

|

Specifications:

Testing:

|

Screwed Bonnet Needle Valve - NPT Male X NPT Male

|

FLUIDLOK Part Number |

End Connection |

SQ (mm) |

L (mm) |

Open (mm) |

Orifice (mm) |

Cv | |

|---|---|---|---|---|---|---|---|

| Inlet | Outlet | ||||||

| SBNV-S-2N-M | 1/8" | 1/8" | 25.4 | 58 | 75.2 | 4 | 0.35 |

| SBNV-S-4N-M | 1/4" | 1/4" | 25.4 | 60 | 75.2 | 4 | 0.35 |

| SBNV-S-6N-M | 3/8" | 3/8" | 25.4 | 60 | 75.2 | 5 | --- |

| SBNV-S-8N-M | 1/2" | 1/2" | 28.5 | 72 | 76.8 | 6 | 0.85 |

| SBNV-S-12N-M | 3/4" | 3/4" | 35.0 | 75 | 80.0 | 6 | 0.85 |

| SBNV-S-16N-M | 1" | 1" | 42.0 | 90 | 94.5 | 8 | 1.20 |

• Dimensions are for reference only. Subject to change.